Description

Specifications

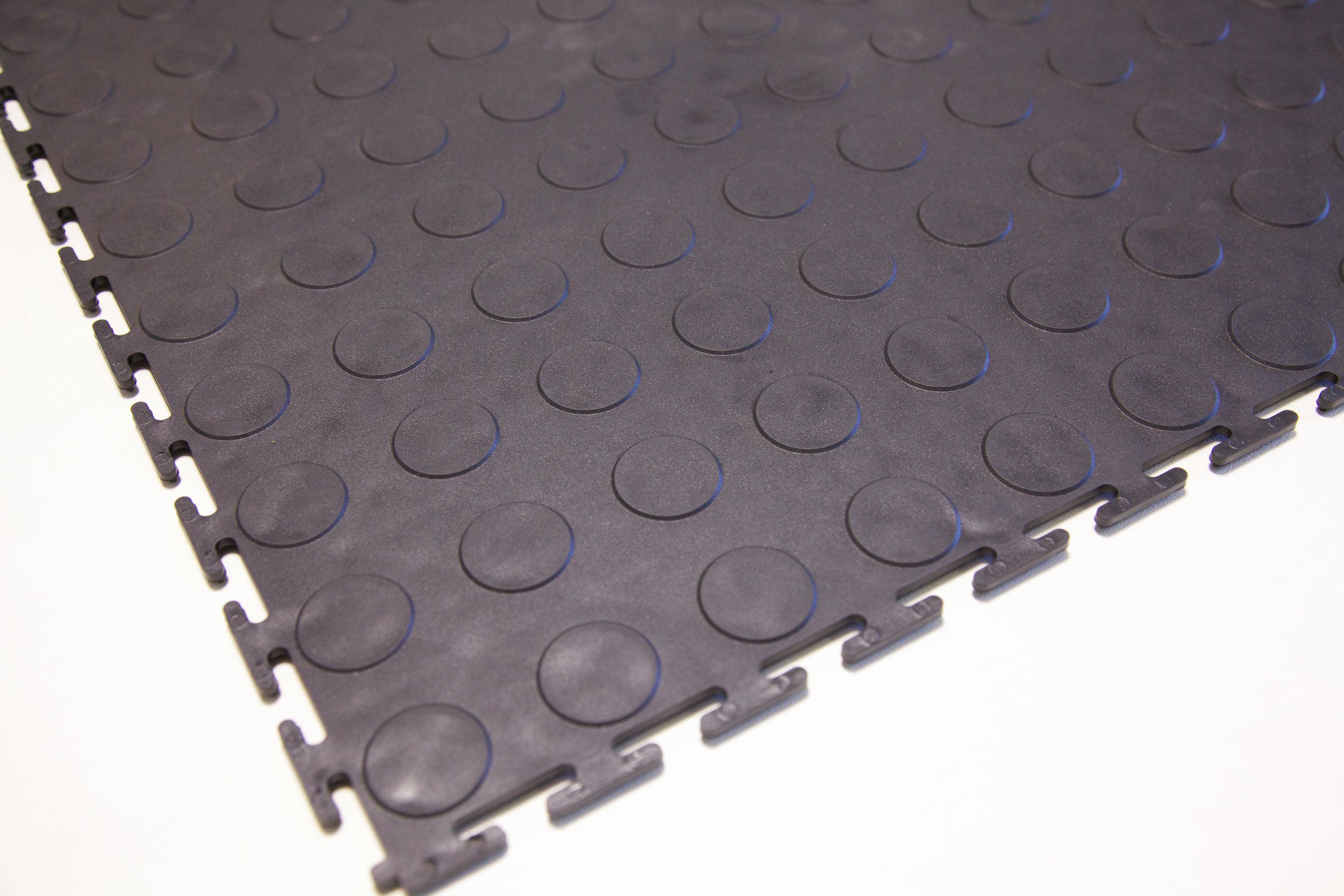

Made of: PVC

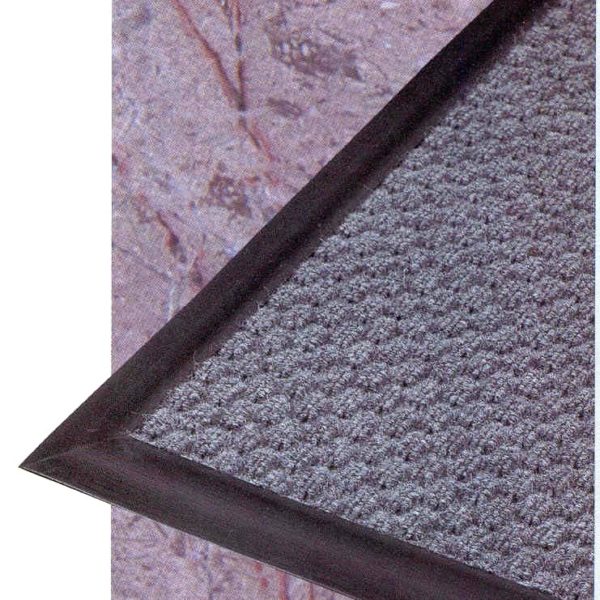

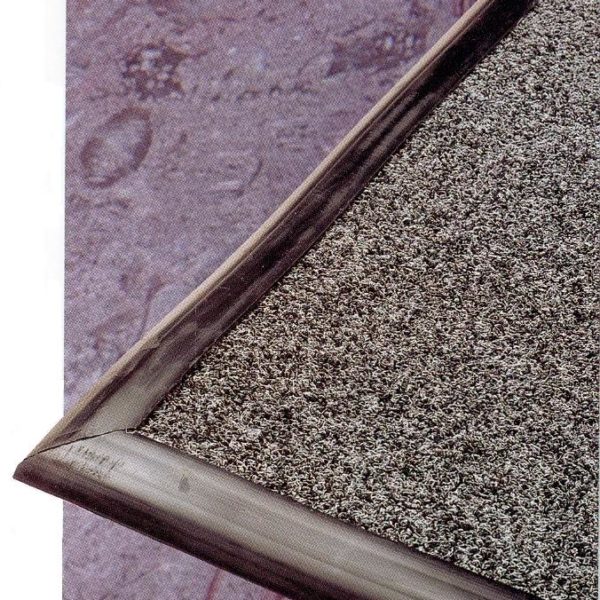

Design: Interlocking tiles with raised disc embossed surface. Grid pattern underside.

Maintenance: Sweep and/or damp mop with a mild detergent. Make sure water does not seep between tiles.

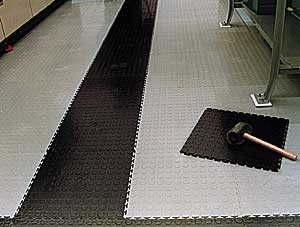

Installation: (adhesive is recommended in applications where it will be subjects to continuous moisture levels)

For SQUARE rooms:

Mark center of room (discounting minor offsets so that tiles at opposite edges of the room are of equal width). Adjust

accordingly to avoid cuts less than 1/2 tile at room perimeters. Lay down 4 tiles at center mark, square to room axis. A

rubber mallet is needed to connect the tiles. Continue towards walls. To create a flush edge against the wall, cut off the

outer tabs, using a utility knife — or — cut tile to fit.

For IRREGULAR rooms:

Start laying tiles at one corner and work your way through the room. A rubber mallet is needed to connect the tiles. To

create a flush edge against the wall, cut off the outer tabs, using a utility knife — or — cut tile to fit.

Sizes and Weights: 19.5″x19.5″ 4.8 lbs 5/16″ thick (approx)

Testing

Resistance: Chemicals and Spillage with 1 hour exposure

Acids: Sulfuric Acid (Conc.) 95% – no effect

Nitric Acid (Conc.) 70% – no effect

Hydrochloric Acid (Conc.) – no effect

Acetic Acid (Conc.) – no effect

Alkalis: Sodium Hydroxide (50%) – no effect

Alcohol: Methyl Alcohol – no effect

Aromatics: Xylene – no effect

Cresol – no effect

Alphatics: Kerosene – very slight surface dulling

Chloroform – surface dulling, surface attack

Ketones and Esters: Acetone – surface dulling, surface attack

Methyl Ethyl Ketone – surface attack

Miscellaneous: Silver Nitrate – very slight surface dulling

Formaldehyde – no effect

10% Betadine – no effect

Clorox – no effect

Tests:

– Passes ASTM E 662-93 Specific Optical Density of Smoke Generated by Solid Materials, also referenced as NFPA 258

– AATCC Test Method 134-1991 Electrostatic Propensity of Carpets

– ASTM E 648-94A Critical Radiant Flux of Floor covering Systems using a Radiant Heat Energy Source, also referred as NFPA

253 and FTM standard 372

– ASTM-C 1028-84 Static Coefficient of Friction

– Golf Spike Resistance Test 25,000 Cycles – Appearance rated good

– Surface Flammability of Carpets and Rugs CPSC FF-170

Physical Properties:

– Hardness – ASTM 2240 (Shore A) 87 or -5

– Moisture Absorption – ASTM-0471 Less than 0.3% by weight (72 hours @ 70ºF)

– Specific Gravity ( or -.02) ASTM D-792 1.37

– Tensile Strength (PSI) ASTM D-412 2700

– 100% Modulus (PSI) ASTM D-412 2200